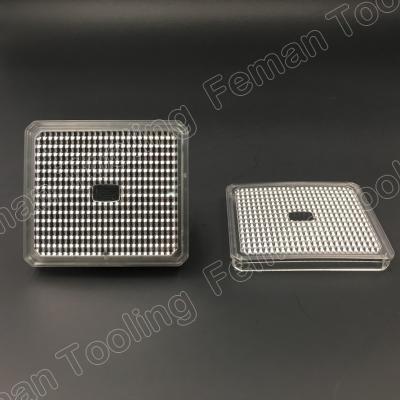

Feman automotive mould is the automotive mould projects and technical development & manufacturing foundation of Feman factory in custom plastic molding china. Feman Automotive strengths in medium and small sized precision and complicated plastic injection mold design and injection manufacture for auto parts mould, main products: door panel, automotive lighting, air conditioning, A/B/C pillars, water tank, instrument panel, glove box assembly, plastic intake manifold, interior trim, grille, air inlet components, gas cap etc. We especially take pride in lighting parts making with high precision CNC engraving and milling machines. The max lighting system mold we made is 1100*1000, 2k plastic injection moulding with transparency and red color.

Injection molding offers numerous advantages for automotive applications. Feman auto parts mould factory specializes in producing automotive molds. The advantages include high production efficiency, allowing for large-scale manufacturing of complex automotive components with consistent quality. It enables precise design flexibility, allowing for intricate geometries and integrated features. Injection molding also provides excellent material properties, such as durability, impact resistance, and chemical resistance, making it suitable for automotive requirements. It offers cost-effectiveness by reducing labor and assembly costs, minimizing waste, and optimizing cycle times. Furthermore, injection molding supports mass production, ensuring consistent part-to-part quality and facilitating quick turnaround times for automotive manufacturers. Overall, injection molding, with Feman's expertise in automotive molds, is a valuable manufacturing process for producing high-quality auto parts.

There are several injection molding materials commonly used for automotive molds due to their specific properties and suitability for automotive applications. Some of these materials, along with their advantages and disadvantages, are as follows:

ABS (Acrylonitrile Butadiene Styrene):

Advantages: Good impact resistance, cost-effective, easy to process, versatile.

Disadvantages: Moderate heat resistance, lower dimensional stability compared to some other materials.

PC (Polycarbonate):

Advantages: High impact strength, excellent transparency, good heat resistance, electrical insulation properties.

Disadvantages: Higher cost compared to other materials, not suitable for outdoor applications due to UV sensitivity.

PP (Polypropylene):

Advantages: Lightweight, good chemical resistance, high fatigue resistance, cost-effective.

Disadvantages: Lower impact strength compared to some other materials, moderate heat resistance.

PA (Polyamide/Nylon):

Advantages: High strength and toughness, excellent wear resistance, good chemical resistance.

Disadvantages: Hygroscopic (absorbs moisture), higher cost compared to some other materials.

POM (Polyoxymethylene):

Advantages: High stiffness, excellent dimensional stability, low friction coefficient.

Disadvantages: Limited resistance to acids and UV light, lower impact strength compared to some other materials.

These are just a few examples of injection molding materials used for automotive molds. The choice of material depends on specific application requirements, including mechanical properties, temperature resistance, chemical resistance, and cost considerations. It's crucial to select the right material that balances performance, cost, and manufacturability for automotive components.

Automotive manufacturers choose injection molding as their preferred manufacturing method for several reasons, especially when it comes to custom selections of automotive injection molding products. Automotive injection molding is a versatile manufacturing process capable of producing a wide range of components for the automotive industry. Some examples of automotive parts that can be manufactured using injection molding include:

Interior Components: This includes parts such as dashboard panels, instrument clusters, door panels, center consoles, seat components, and trim pieces.

Exterior Components: Automotive injection molding can produce exterior parts like bumpers, fenders, grilles, side mirrors, door handles, and body panels.

Lighting Components: Injection molding is used to manufacture headlights, taillights, turn signals, fog lights, and other lighting elements.

Engine Components: Parts like intake manifolds, valve covers, oil pans, and engine mounts can be produced using injection molding.

Electrical Components: Automotive injection molding is used to manufacture connectors, switches, wiring harnesses, fuse boxes, and sensor housings.

HVAC Components: Injection molding can produce components for heating, ventilation, and air conditioning systems, such as air vents, control knobs, and fan housings.

Safety Components: This includes parts like airbag housings, seat belt components, and structural reinforcements.

These are just a few examples of the many automotive components that can be manufactured using injection molding. The process offers design flexibility, cost-effectiveness, and high production efficiency, making it a preferred choice for producing a wide range of automotive parts.